Develosil FlexFire UHPLC and HPLC Columns INDIA

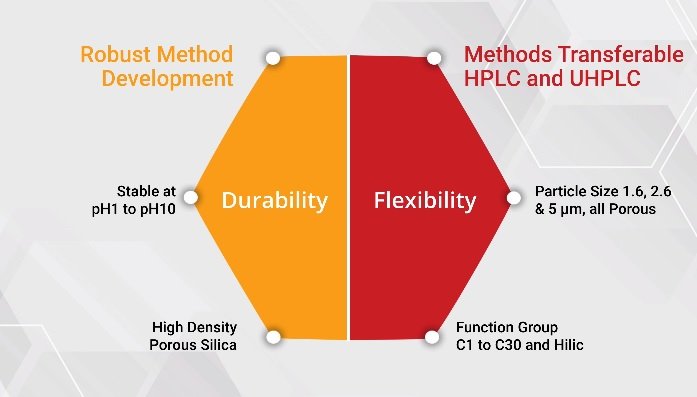

FlexFire’s value and performance lies in its high-quality silica, the lifeblood at the heart of its creation. Applying 40 years of manufacturing expertise and an upgraded production system, Develosil has upgraded to the highest grade uniform, high-density, low-metal porous silica. With improved end-capping technology Develosil withstands the harshest of conditions and delivers use after use, beyond the highest expectations.

Flexibility

HPLC-UHPLC Method Transferability

FlexFire series provides 1.6, 2.6 and 5 µm particle sizes to fit the requirements of your analytical systems, both HPLC and UHPLC. This wide range of options allows the same line of columns to be used in different departments, such as R&D and QC (quality control).

FlexFire dramatically shortens the required time for tweaking the optimal condition from one particle size to another. This is because the excellence and homogeneity of the silica gel, end-capping, and bonding of functional groups provide predictable consistency across all of the FlexFire columns.

The figure below shows HETP and column pressure at different flow rates. Smaller particle size provides higher resolution across a wider range of flow rates.

Example of method transfer between HPLC and UHPLC

FlexFire displays the same surface area ratio of 340 m2/g, the same physical properties, and the same bonding of functional group and end-capping on three different particle size silica substrates.

As a result, by choosing the correct column dimensions users can maintain equivalent resolution while shifting between particle sizes. This great feature makes it simple to transfer methods between different particle sizes. Chromatography software can be used to determine the flow rate and gradient without trial and error, as no adjustments are necessary after the calculation.

If you are using UHPLC during R&D and HPLC during QC, FlexFire will save time previously spent re-adjusting the analytical conditions to find the best resolution. If you are planning to adopt UHPLC in the future, you can start with FlexFire 2.6 µm or 5 µm columns without worries.